The technology

Delivering cost-effective and scalable energy solutions though exceptional engineering.

Overview

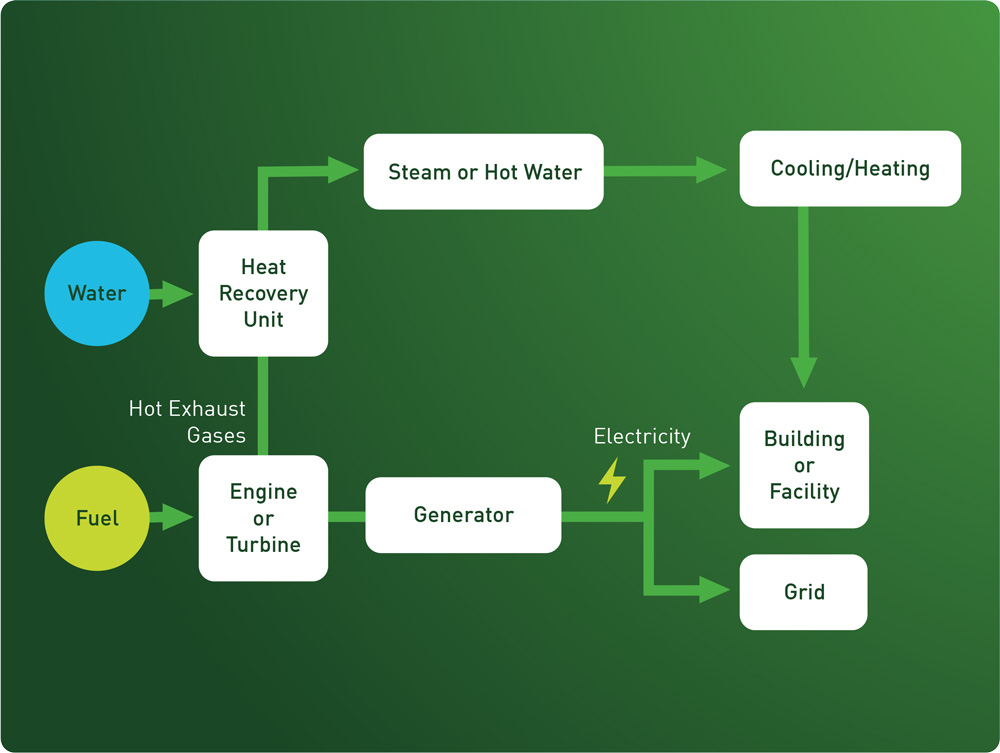

Our solution is based on the Stirling-engine combined heat and power (CHP) technology that was developed by Scottish engineer, Robert Stirling, more than 200 years ago. A revolutionary of his time, his heat engine was vastly different to the internal combustion engine, operating on a cycle of compression and expansion of air or gas. To operate, it only needed an external heat source as wasted heat. The regenerator component, which stored heat from one cycle to be used in the next one, delivered greater efficiency and higher power.

Every engine or motor emits heat and what we have done is taken this waste heat and, through exceptional engineering, turned it into a viable electrical source using our waste heat recovery (WHR) system.

The detail

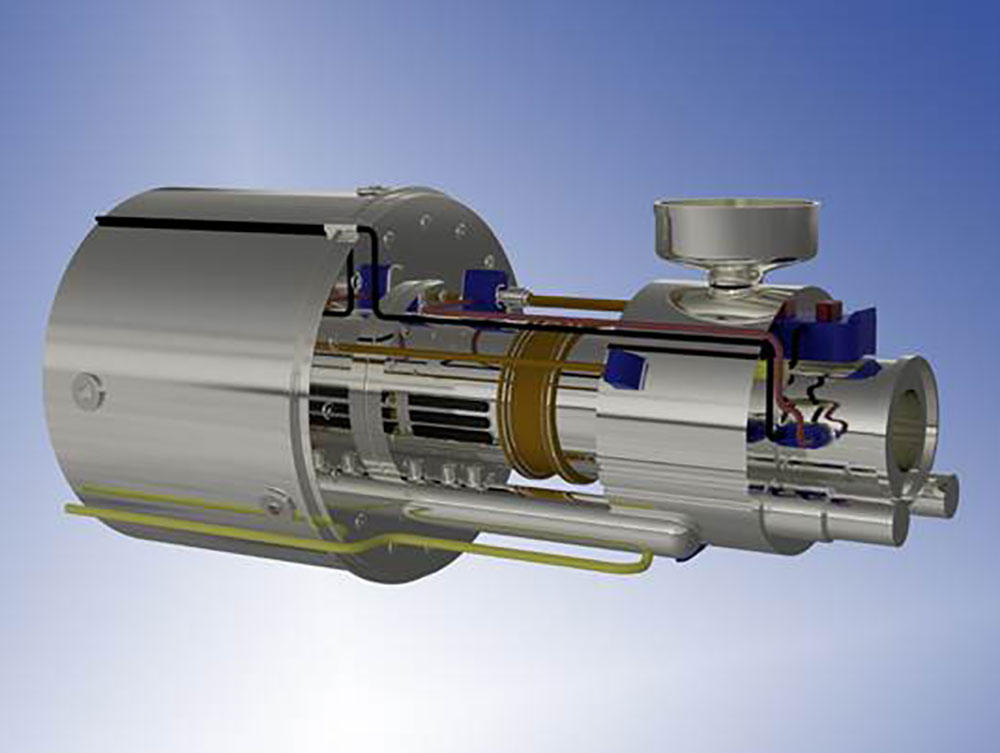

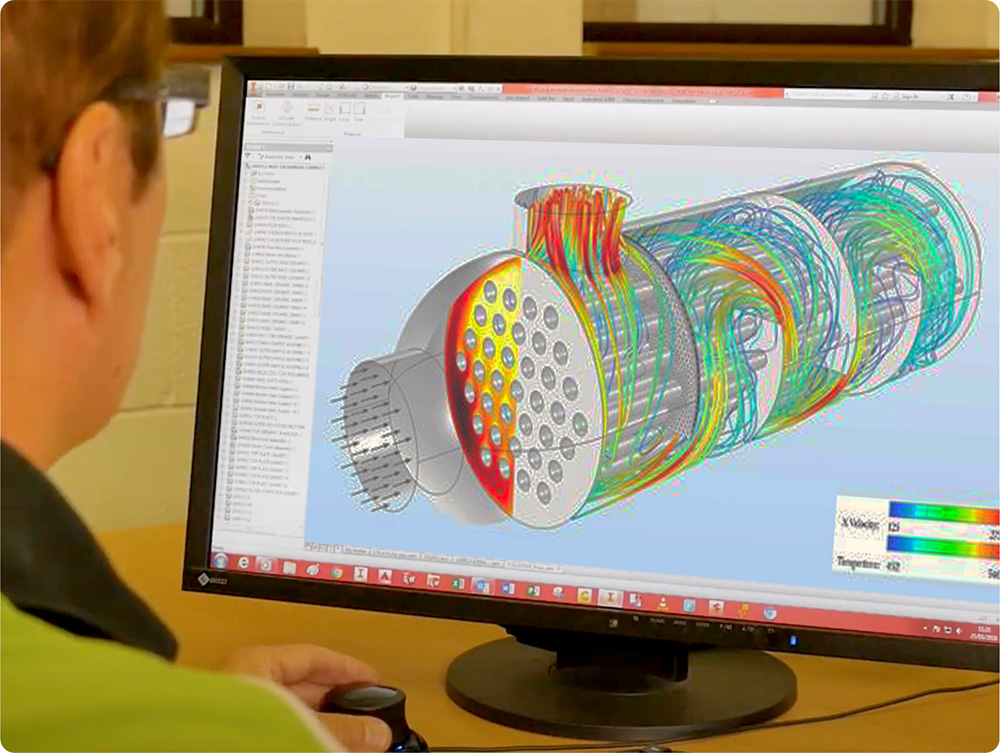

Based on the Stirling principle, we recycle helium through the system, heating and cooling it in 1/5 of a second. The unit is charged with helium at assembly stage because it is a gas that tolerates compression as well as heat. It is then compressed down to 95 bar, enabling it to generate as much power stroke as possible. With a displacer and power action we achieve a

rotational movement that increases from 3,500 rpm to 14,500 rpm which is transferred through an alternator into an electrical source. Our alternator design has been specifically engineered for our solution and is unlike any other available on the market today.

We have re-examined and re-engineered the Stirling CHP technology to maximise the power source from the unit. By heating and cooling the helium from 680°C to 135°C within 1/5 of a second and reciprocating it through the entire system, the actual heat that is vented out of the exhaust is around 60°C and has a far lower carbon footprint than would be without our process and is more environmentally friendly.

Benefits

Sustainable

Regenerating energy for a sustainable future.

Scalable

Brilliant engineering with no restrictions.

Applications

Modern technology with unlimited possibilities.

Efficient

Smart solutions for energy efficiency.

The Inspirit Charger

Developed over a number of years and based on the Stirling engine, the Inspirit Charger micro combined heat and power boiler (micro-CHP) has an ultra-high level of energy efficiency of 90%. It provides multiple benefits including a reduction in energy cost and carbon footprint and lessens reliance on electricity from the national grid.

The Inspirit Charger can be installed as a standalone, or as the lead appliance in a plant room and produces 6.4kW electrical and 15kW thermal output. Its green credentials mirror those of our other technologies and solutions.

The Inspirit Helix Accelerator

We have also applied our exceptional engineering minds to design and develop the Inspirit Helix Accelerator. Sitting alongside our WHR system, it uses the initial heat source and by exothermic reaction – created by boron oxide and cadmium – increases the heat by at least 26%.

For those companies who don’t believe they have a heat source sufficient to run the WHR cycle, the Inspirit Helix Accelerator will ensure they don’t miss out on cost and environmental benefits.

Register your interest

To follow our technology for a sustainable future, please enter your email address to register your interest.